A servo drive is an electronic amplifier used to power electric servomechanisms.

The NX Series servo motor drivers allow for easy operation and control of the servo motors. 4 Control Modes are available: Position, Speed, Torque and Tension Control. The driver provides automatic tuning allowing for optimal performance without manual adjustments. A servo drive takes the command signal for position, velocity or current and adjusts the voltage and current applied to the servo motor based on closed-loop feedback. A servo drive is an element of a motion control system which includes a servo motor, servo drive controller and feedback element, usually as part of the servo motor.

A servo drive monitors the feedback signal from the servomechanism and continually adjusts for deviation from expected behavior.

Function[edit]

A servo drive receives a command signal from a control system, amplifies the signal, and transmits electric current to a servo motor in order to produce motion proportional to the command signal. Typically, the command signal represents a desired velocity, but can also represent a desired torque or position. A sensor attached to the servo motor reports the motor's actual status back to the servo drive. The servo drive then compares the actual motor status with the commanded motor status. It then alters the voltage, frequency or pulse width to the motor so as to correct for any deviation from the commanded status.[1]

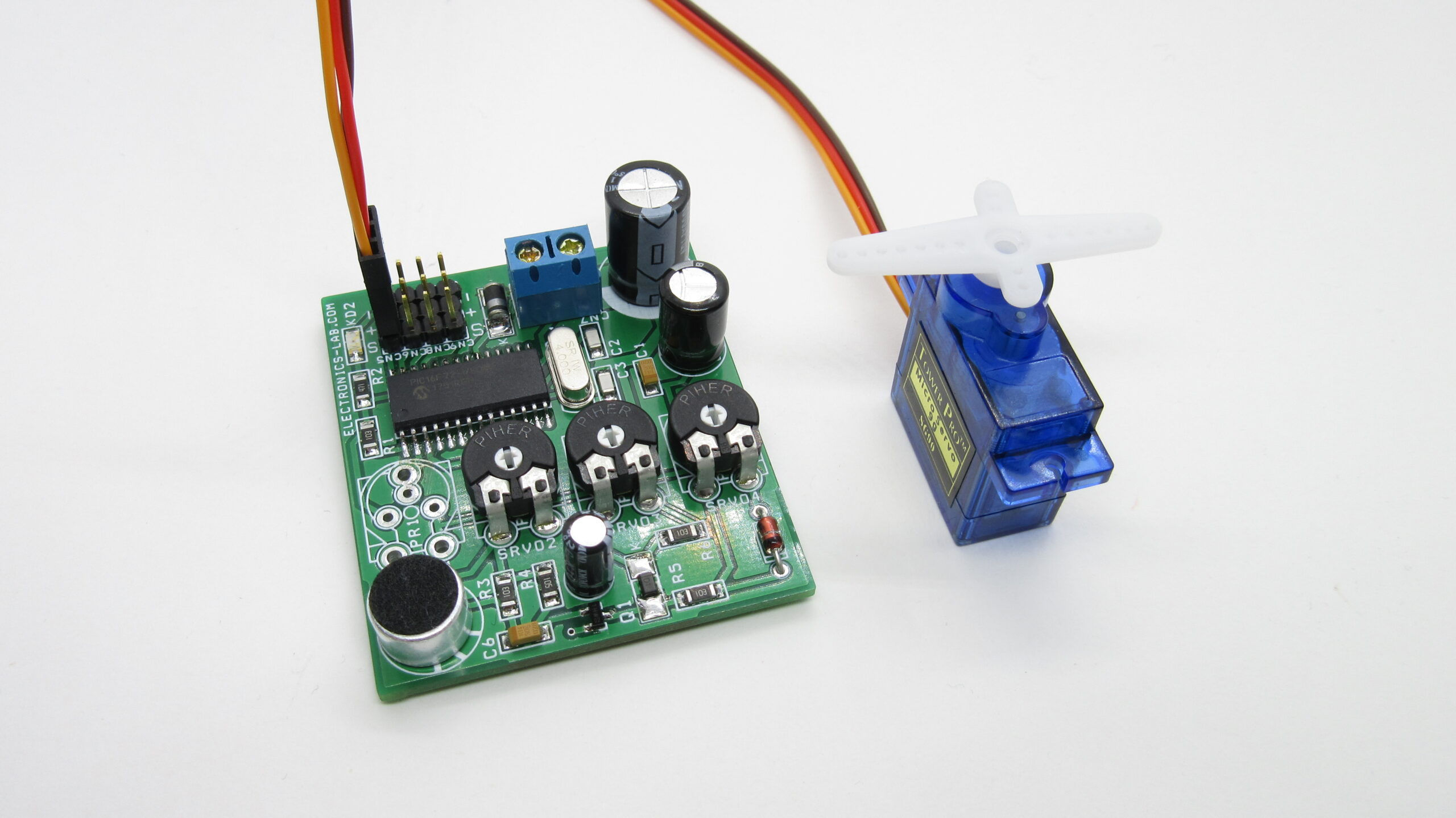

Our servo drives range from 300 watts to 50,000 watts of continuous duty power output. With peak operation for a full 5 seconds in certain drives, often 3 times the rated continuous current, many applications can use significantly smaller servo drives and expands the dynamic performance of the servo drive lineup. Motors and Drivers - Servo Driver! Micro Maestro 6-Channel USB Servo Controller (Assembled) ROB-17507. Favorited Favorite 1.

In a properly configured control system, the servo motor rotates at a velocity that very closely approximates the velocity signal being received by the servo drive from the control system. Several parameters, such as stiffness (also known as proportional gain), damping (also known as derivative gain), and feedback gain, can be adjusted to achieve this desired performance. The process of adjusting these parameters is called performance tuning.

Although many servo motors require a drive specific to that particular motor brand or model, many drives are now available that are compatible with a wide variety of motors.

Digital and Analog[edit]

Most servo drives used in industry are digital or analog. Digital drives differ from analog drives by having a microprocessor, or computer, which analyses incoming signals while controlling the mechanism. The microprocessor receives a pulse stream from an encoder which can determine parameters such as velocity. Varying the pulse, or blip, allows the mechanism to adjust speed essentially creating a speed controller effect. The repetitive tasks performed by a processor allows a digital drive to be quickly self-adjusting. In cases where mechanisms must adapt to many conditions, this can be convenient because a digital drive can adjust quickly with little effort. A drawback to digital drives is the large amount of energy that is consumed. However, many digital drives install capacity batteries to monitor battery life. The overall feedback system for a digital servo drive is like an analog, except that a microprocessor uses algorithms to predict system conditions.

Analog drives control velocity through various electrical inputs usually ±10 volts. Often adjusted with potentiometers, analog drives have plug in “personality cards” which are preadjusted to specific conditions. Most analog drives work by using a tach generator to measure incoming signals and produce a resulting torque demand. These torque demands request current in the mechanism depending on the feedback loop. This amplifier is referred as a four-quadrant drive because can accelerate, decelerate and brake in either rotating direction. Traditional analog drives consume less energy than digital drives and can offer very high performance in certain cases. When conditions are met, analog drives offer consistency with minimal “jitter” at standstills. Some analog servo drives do not need a torque amplifier and rely on velocity amplifiers for situation where speed is more important.[2][3]

Use in industry[edit]

Servo systems can be used in CNC machining, factory automation, and robotics, among other uses. Their main advantage over traditional DC or AC motors is the addition of motor feedback. This feedback can be used to detect unwanted motion, or to ensure the accuracy of the commanded motion. The feedback is generally provided by an encoder of some sort. Servos, in constant speed changing use, have a better life cycle than typical AC wound motors. Servo motors can also act as a brake by shunting off generated electricity from the motor itself.

See also[edit]

References[edit]

- ^Servo drive manual

- ^'Drive Technologies'(PDF).

- ^RcHelpDotCom (2011-05-02), Analog vs Digital Servos, What's The Difference, retrieved 2019-02-14

Updated August 2019 || Servo systems consist of four main components — a motor, a drive, a controller, and a feedback device … with the latter usually an encoder. The controller determines what the motor must do and then triggers the drive to send the necessary electrical energy to the motor to make the required move happen.

More specifically, the controller is responsible for calculating the path or trajectory required and sending low-voltage command signals to the drive.

The drive then sends the necessary voltage and current to the motor to achieve the required motion.

Servo drives can control torque, velocity, or position … although in servo systems, the most common parameter controlled is torque.

Note that servo drives are also sometimes called amplifiers because they take the control signal from the controller and amplify it to deliver a specific amount of voltage and current to the motor.

There are several types of servo drives. A common variation is the torque-mode amplifier. These convert the command signal from the controller into a specific amount of current to the motor. Because current is directly proportional to torque, the drive is controlling the amount of torque that the motor produces.

In contrast, with a linear drive (in which current is proportional to force) there’s direct control of the motor’s force output.

Remember that servo-motor torque is directly related to current:

T = KT × I

Where:

T = Torque

KT = Motor constant

Servo Driver Ic

I = Current

To use an analogy …

• As the brains of the system, the job of the controller is to take information from the feedback device and send the appropriate voltage signals to the drive.

• The drive acts as the nervous system and sends the necessary amount of current to the motor. This process of reading and responding to feedback makes the system closed loop … which is the defining characteristic of a servo system.

One of the most important tools for sizing a servo motor is its torque-speed curve. But often, the torque-speed curve is specific to a certain motor-drive combination. This is because the continuous and peak torque capabilities of the motor are affected by the thermal properties of both the motor and of the drive. Inefficiencies in the motor cause it to produce heat, which can degrade bearing lubrication and insulation around the windings. Excessive heat — typically caused by running a motor above its peak torque — can demagnetize the motor’s magnets.

Although the drive has no moving parts, heat can damage its power transistors.

Note that continuous torque is the amount of torque the motor can produce indefinitely. Peak, or intermittent, torque is the maximum amount of torque the motor can produce, but peak torque can only be sustained for a short amount of time before overheating occurs.

Term “servo drives” also sometimes refers to integrated motors

Servo drives were originally stand-alone components, separate from the motor and controller. But in the past 15 years or so, numerous motor manufacturers have developed integrated drive-controller offerings … as well as integrated motor-drive systems … and even complete motor-feedback-drive-controller systems.

Slightly complicating matters is that these integrated designs (which include the motor, feedback, controller, and drive) are sometimes simply called drives for their axis-driving function. They tend to reduce wiring, make sizing and selection easier, and save considerable space and setup time.

Feature image courtesy Schneider Electric ⚙️ Article updated August 2019.

Servo Driver Definition

You may also like: